How Long Does It Take to Make a Challenge Coin

The challenge coin manufacturing process is dependent on your design and current order volume. Most orders take between 2 and 5 weeks.

Design and current production load dictate how long a coin takes to make. While most coins could be made in 10 days, if they move right from one step to the next, there is often a pause between processes due to order volume.

The first order of business is creating a custom mold for the design. After that, all of the coins need to be stamped, plated, deburred, individually colorfilled and put through quality control before shipping out.

Here is how the whole process looks like:

First 12 hours

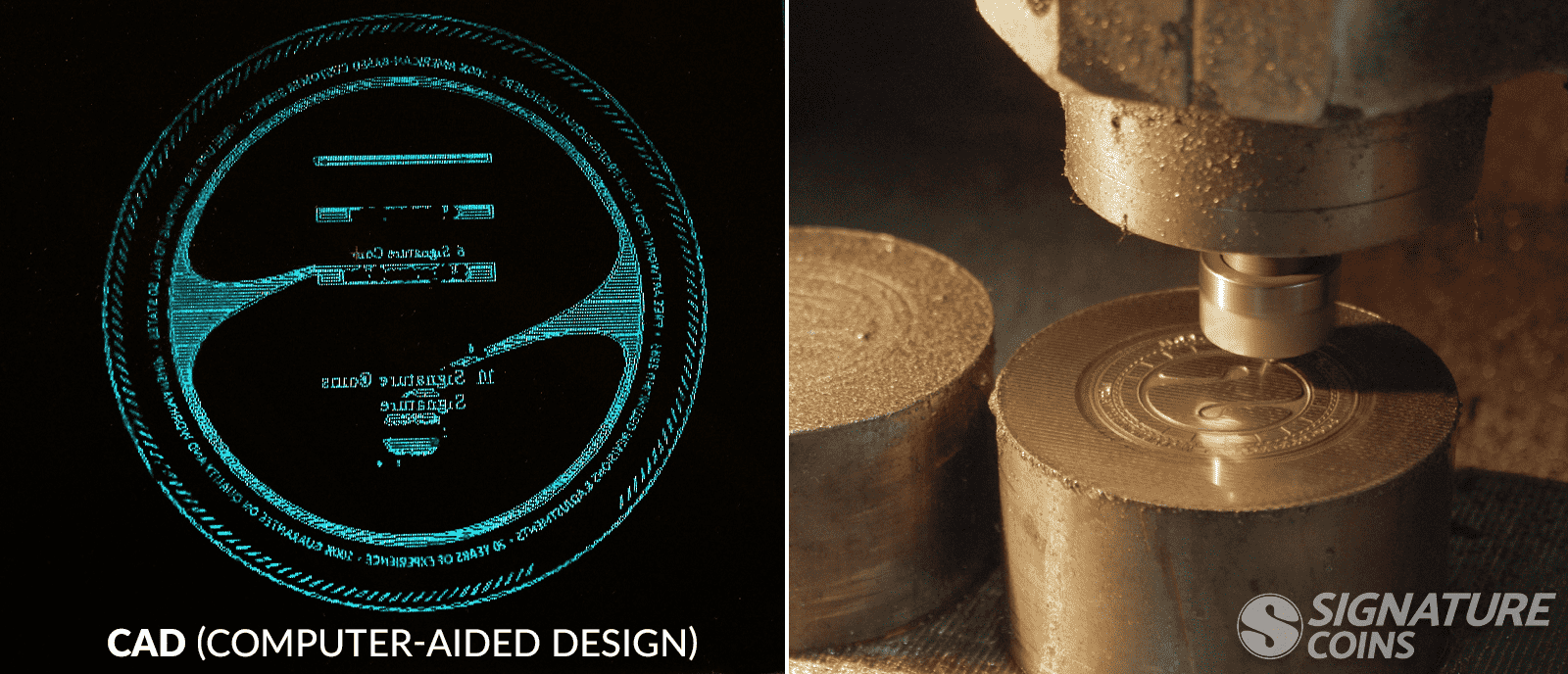

Artwork goes through quality control where one of our production managers ensures that the coins can be produced accurately and consistently. Once this is finished, we start making the custom mold.

Day 1

For most orders, molds are ready within the first 24 hours and all of the coins are stamped and ready to move to the deburring stage of production.

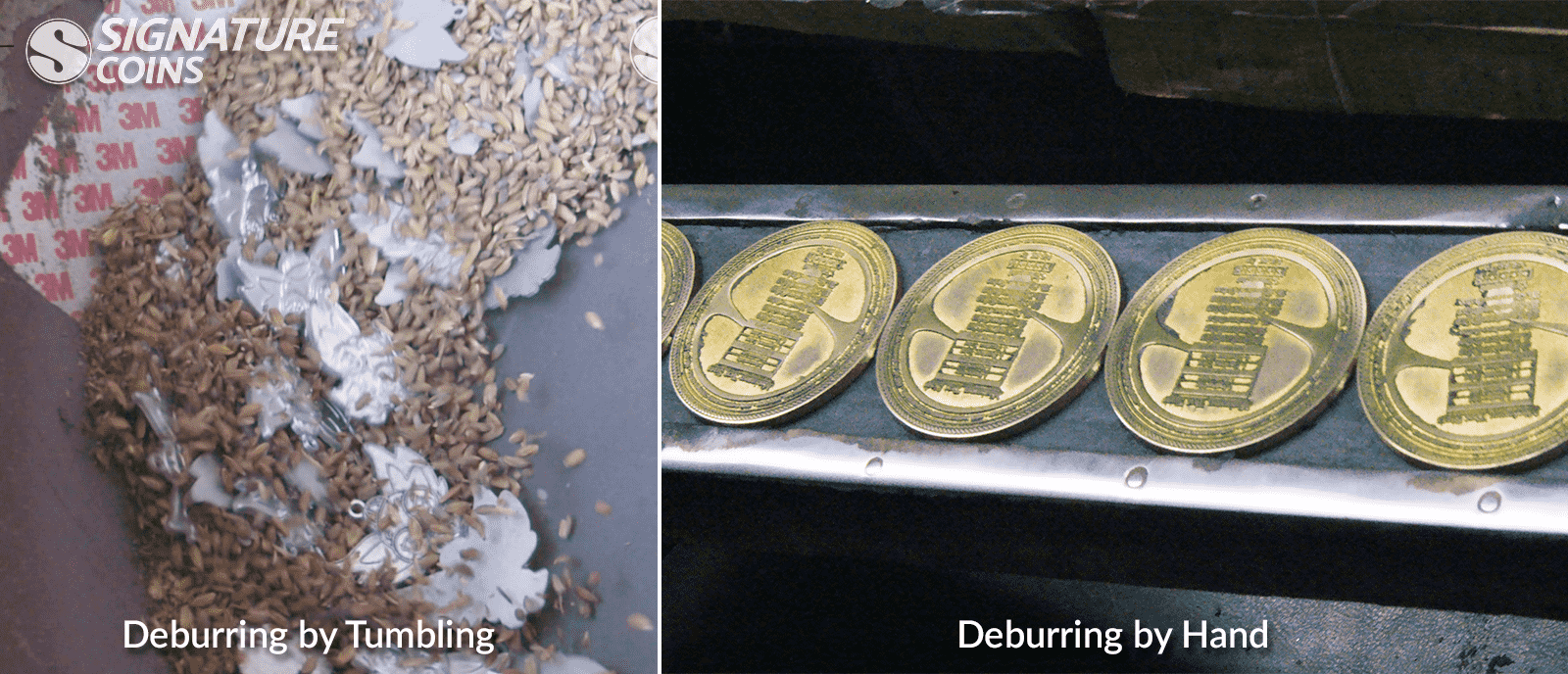

Day 2

By the end of the second day, all of the coins will have gone through the deburring process, which involves smoothing out any rough edges, ridges or imperfections from each coin. Once this is complete, coins move onto the plating stage of production.

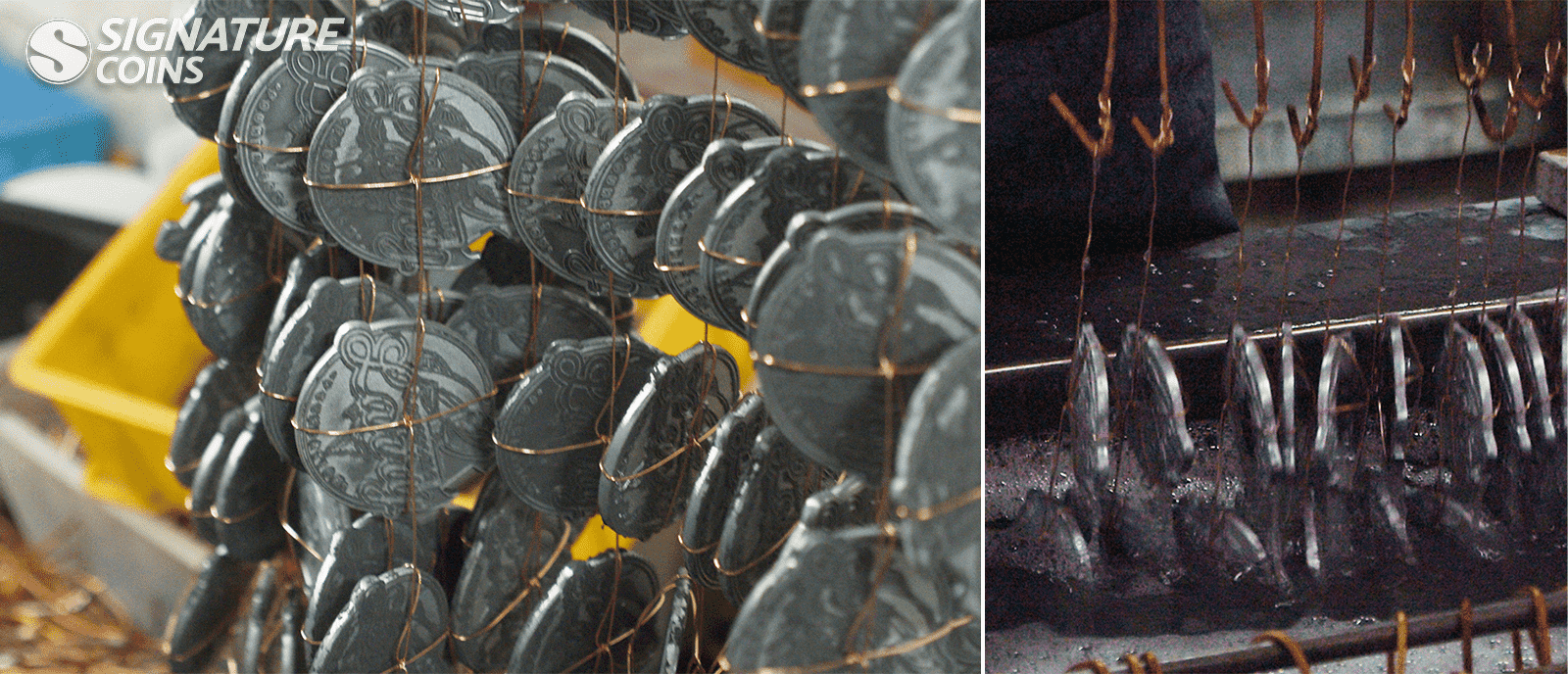

Days 3 - 5

Plating can take anywhere from one to two days. The process involves running an electrical current through a solution containing a customer’s chosen plating option and then adding the bare metal coins. The time this takes can be dependant on the number of coins and the complexity of the plating chosen (dual plated coins take longer).

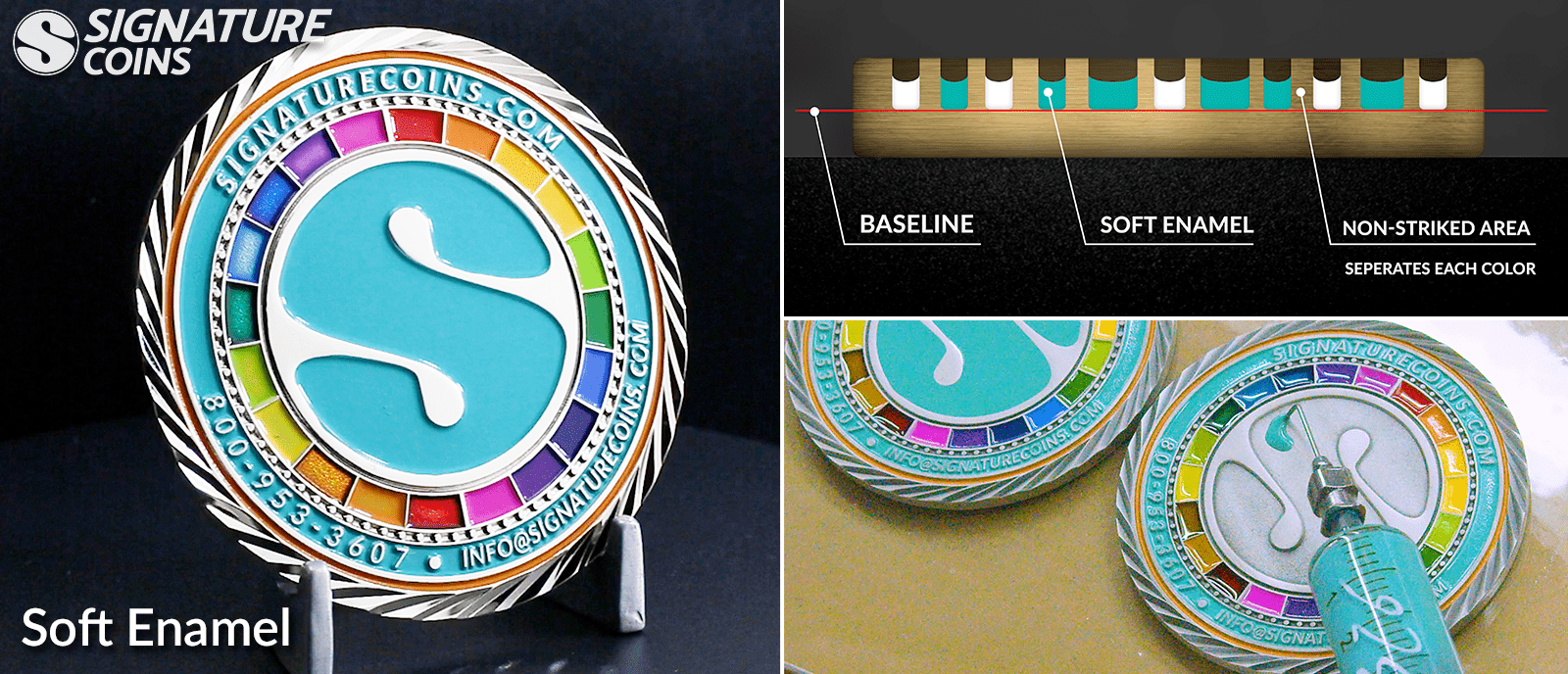

Days 5 - 8

The colorfilling process is the last major part of coin construction. For designs made up of individual colorfill areas, those areas need to be painted one by one.

Days 8 - 10

The last two days of production are spent adding any finishing touches to the coins, polishing the entire set of coins and going through one last quality control check. Once everything is checked and packaged, the coins are mailed out via UPS next day air.

Days 10 and Up

Some orders can be completed and delivered within just three days and others take 4-6 weeks. The most important thing is to communicate your expectations and needs to the sales team!

Things that can extend the length of production are options like 3D designs, dual plating and colorfilling. 3D coin molds take longer to machine than 2D molds, and dual plating can take twice as long as the single plating process. Coins with a large number of individual colorfill areas will take more time as well since each colorfill area is completed individually.

Things that help shorten production time are choosing 2D and bare metal designs that do not require special plating or painting. These types of coins can be finished and shipped out within one or two days.

Challenge Coin Customer Reviews

Support Topics

Resources

- Challenge Coin Design Template

- Challenge Coin Checklist

- How to Design a Challenge Coin 101

- Learn how challenge coins are produced

Production

- What is the turnaround time for a challenge coin order?

- How are Challenge Coins made?

- What kinds of paints are used to add color to my coin?

- What is Sandblasting?

- What is Die Casting?

- What's the difference between a cloisonne, die struck and standard soft enamel?

- Where are your coins made?

- How long do you retain my coin mold once an order is placed?

- How Long Does It Take to Make a Challenge Coin?

- How long do you retain my coin mold once an order is placed?

- How do I know when my coin mold is going to expire?